NDT Inspection Services

Turnkey NDT Inspection Services To Keep Your Asset Online

Additional Inspection Services

When it comes to inspections, working with the fewest set of contractors reduces logistical headaches and streamlines communications. To be a turnkey provider, Gecko Robotics compliments its robotic ultrasonic capabilities with traditional NDT capabilities giving clients a full range of options to achieve their inspection goals.

These services are conducted during the same mobilization and under the watchful eye of the same supervisor. This provides the highest scope completion and ensures that measurements adhere to the same rigorous standards for accuracy.

Services

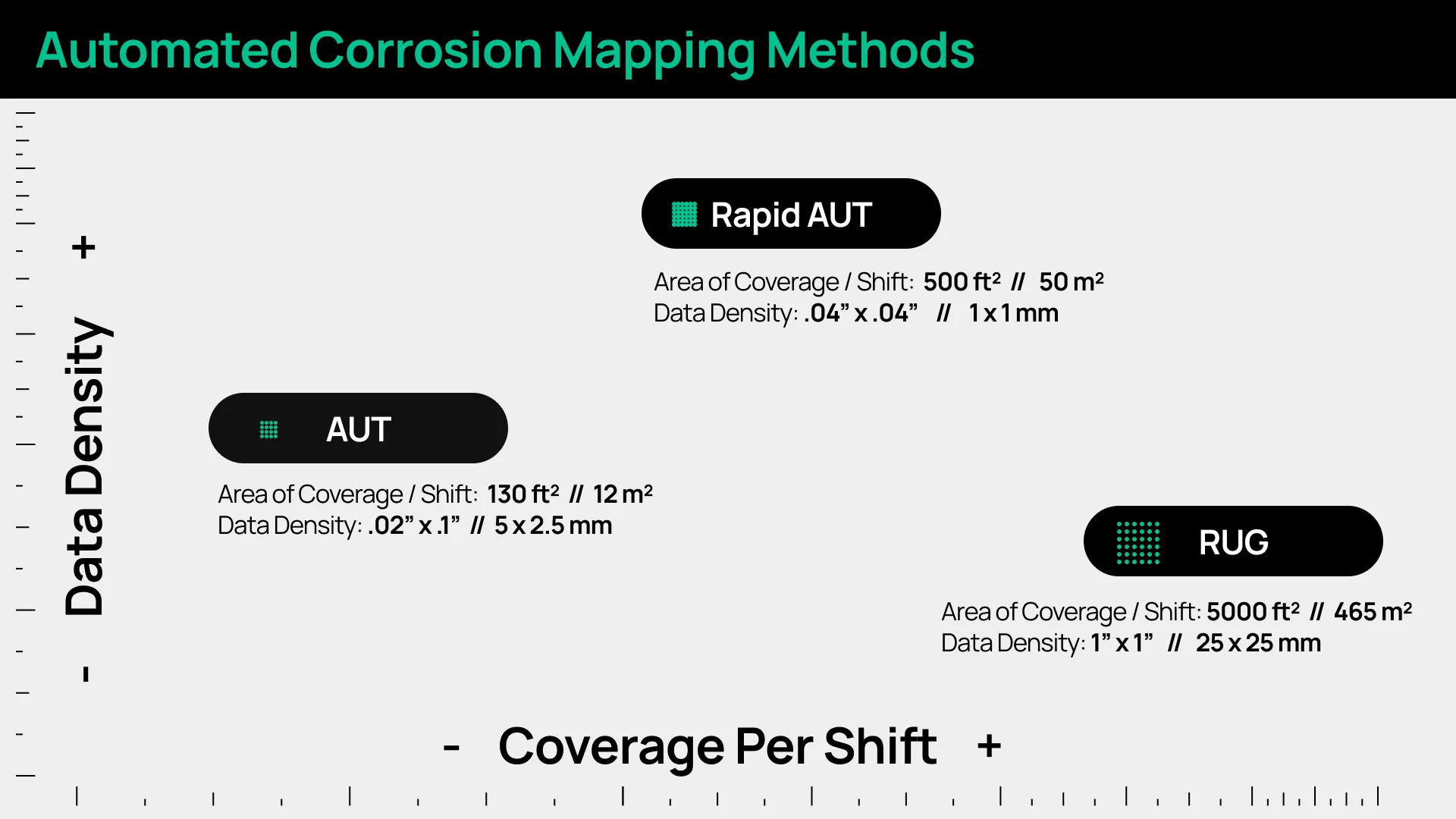

Rapid Ultrasonic Gridding (RUG)

A RUG inspection is a robot-enabled ultrasonic inspection that produces thickness grid maps to identify areas where corrosion and other damage mechanisms have caused wall-thinning. It is Gecko’s fastest robotic service, designed to cover an entire asset in as little as one shift. RUG is a replacement for traditional hand-held gridding with variable grid sizes from 12” x 12” to ¼” x ¼” (0.3 x 0.3m to 6 x 6mm). It is suitable for any ferritic surface with temperatures up to 275° F (135° C). Typical RUG inspections collect 1000X more data at 10x faster inspection times.

Rapid Automated Ultrasonic Testing (R-AUT)

When precision matters, operators turn to AUT to dive deeper into areas of corrosion and other trouble. Due to production speed and cost of current technologies, AUT is usually deployed on small areas. But, not any more! Gecko Robotics in-house engineers have designed Rapid-AUT to overcome this challenge. Taking advantage of PAUT technology, Rapid-AUT covers up to 600 sqft (56 sqm) in one 12-hr shift with millimeter resolution. This is 5x the speed with significantly improved data density.

.gif)

Tri-Lateral Phased Array (TriLat)

A revolutionary robotic ultrasonic testing method for the on-stream inspection of fixed equipment in sour service. TriLat identifies wet H2S damage mechanisms, including Hydrogen Induced Cracking (HIC), Stress Oriented HIC (SOHIC), and Sulfide Stress Cracking (SSC) in carbon and low alloy steel equipment at unprecedented productivity and resolution. Driven by the same robotics and rastering as Rapid AUT, but instead utilizes a state of the art probe for identifying subsurface cracking and damage at the earliest stages.

Automated Weld Inspection

Gecko Robotics provides phased array weld inspections to complement its core RUG and Rapid-AUT mapping inspections. The inspection covers weld seams, heat-affected zones (HAZ), flanges, and any other areas prone to cracking (SCC, HIC/SOHIC, etc) or other damage mechanisms (HTHA, etc). Provided both manually and robotically, the GRIT team has the tools to inspect anywhere you need in the shortest possible time. All data is reviewed by our Level III inspectors to identify and characterize any damage present.

Gecko Robotics Inspections Team (GRIT)

We pride ourselves on our professionalism and customer service throughout the entire inspection process. This starts with a consultation to determine scope. Via a walkdown or review of technical drawings, the inspection plan is created and transparently priced. Before the inspection commences, a project manager reviews the site logistics, safety requirements and conducts a virtual walk-through of the inspection with the client. Once on-site, the Gecko Robotics Inspection Team (GRIT), consisting of trained Level II/III inspectors, diligently executes the inspection plan to meet time and budget constraints. Preliminary data is reviewed before the GRIT team leaves the site, with the final report delivered on average 48 hours later.

Gecko Portal - Interactive Deliverables

The Gecko deliverable is unique to the industry. All inspection data is available via our online web portal called Gecko Portal®. It interactively displays inspection data in 2D and 3D formats and easily shared with contractors, engineers, and management for full visibility. Each and every Gecko inspection and report is filed under an intuitive site hierarchy so you’ll never misplace your inspection data again. An unlimited number of users can be added to the portal and raw data can be downloaded at any time.